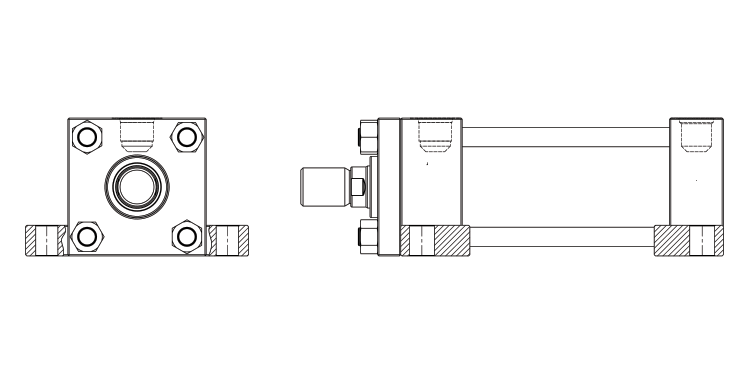

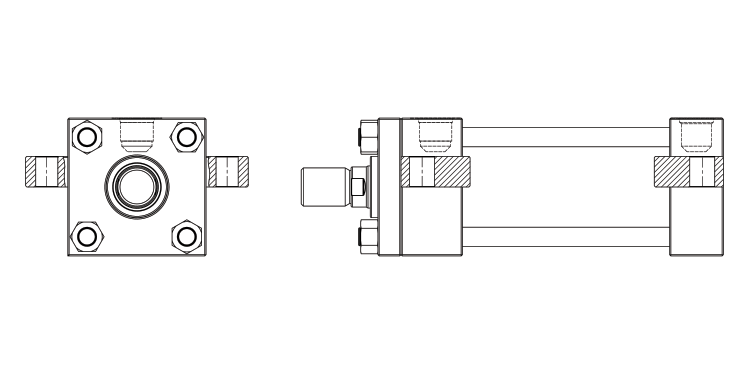

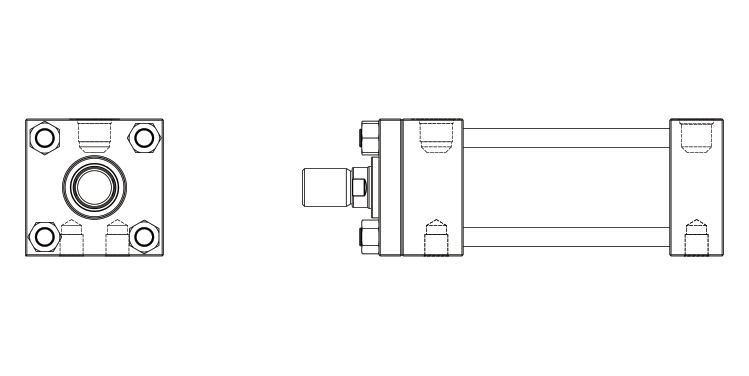

Heavy Duty Hydraulic Cylinders

Standard bore sizes up to 12" with pressure ratings of up to 3000 PSI, depending on mount and stroke. All Higginson cylinders are available with non-standard options such as stainless steel, high-temp seals or use with exotic fluids. We offer all NFPA mounts in addition to custom mounts, which we proudly manufacture in one of the industry's quickest lead times.