If you're not a fluid power industry professional, hydro-pneumatic accumulators are a bit of a mystery. You may have them on your machine, on your power unit, or another location in your hydraulic system, but you may not even know why they’re used. They’re important objects recommended for various useful fluid power tasks … so important that I’m making my list of Top 5 Reasons to Use an Accumulator.

1. Accumulators dampen the pulsation-related noise of hydraulic pumps. The pressure waves created as a pump's gears, vanes or pistons reach the pressure side, creating a telltale high-pitched hydraulic cacophony. It’s annoying at best and ear-splitting at the worst.

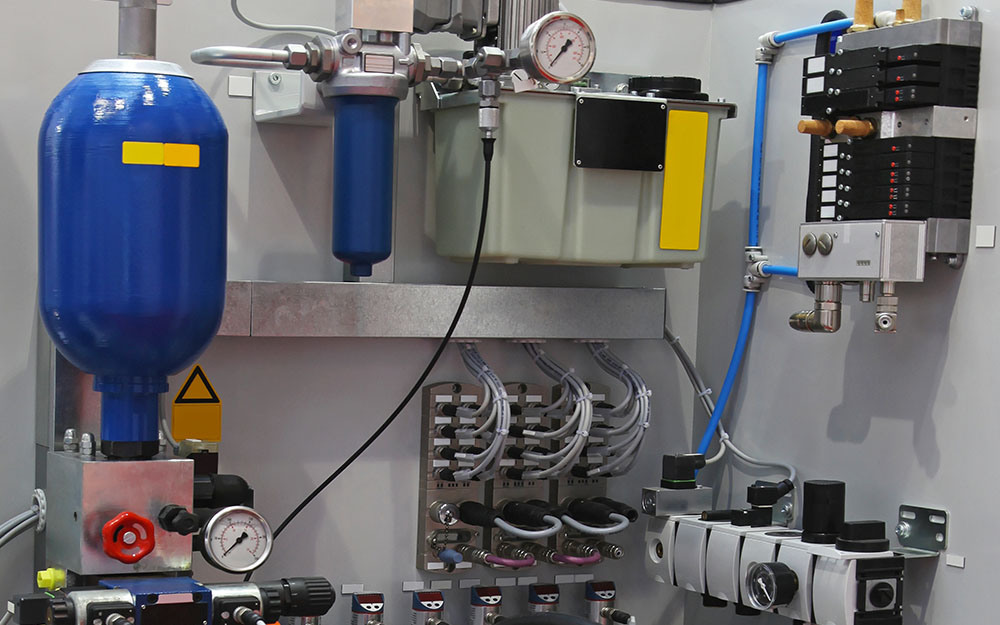

A diaphragm accumulator absorbs the pressure spikes of the pump, dampening the pulse before it can turn into that screech. The key is sizing the correct accumulator volume and precharge pressure to match the pump frequency in question.

2. Accumulators provide high auxiliary flow for machines with a low duty cycle. Machines that run a high flow operation (like a press) with time between cycles makes a perfect candidate for accumulators.

A smaller pump can run continuously, partly to power the primary operation or charge the accumulators. When the high-speed function is required, both the accumulator(s) and pump provide flow. When the function is idle, the pump charges the accumulator(s) to prepare for the next cycle.

3. Accumulators provide emergency hydraulic energy. If you experience a power failure eliminating your pump's power source, an accumulator offers a source of backup energy, much like a battery backup for your computer. The accumulator permits retracting, opening, or other function to return your machine to its safe mode. No amount of backup storage is limited, either, as accumulators banked together provide potentially hundreds of gallons of store fluid under pressure.

4. Accumulators permit clamping functions during a period of power unit idling. A machine tool clamp, for example, could be plumbed in parallel with an accumulator to hold clamp pressure for extended machining operations. The accumulator volume only needs to be large enough to overcome any possible leakage during the machine cycle.

5. Accumulators stabilize work pressure in dynamic machines. When you tie an accumulator into a machine's primary or work lines with fluctuating load pressure, the accumulator will send or absorb hydraulic fluid as required to raise or lower pressure to a stable level. For example, this function may be necessary for hybrid systems using clamping pressure and other high-velocity operations.

Regardless of your reason to need an accumulator, Higginson is the place to get it. We stock hundreds of diaphragm and bladder accumulators, along with all the standard repair kits and parts. Get in touch to see how we can engineer an accumulator to help you with your machine.